Model:CBAV-14R155

Standard:ASME B16.34

Size:1/2" ~ 8"

Pressure:150LB(PN10)

Estimate Delivery:35 days

Size: 1/2” – 8” (DN15-DN200) Full Bore Construction

1-1/2” – 10” (DN15-DN200) Reduced Bore Construction

Pressure: Clas150-Class300 (PN10-PN40)

Available Manufacturing Standards: ASME, JIS, DIN, GOST etc.

Available Liner Ceramic Materials: Al2O3, ZrO2, Si3N4, SiC

Available Ball Port type: Round type or V type.

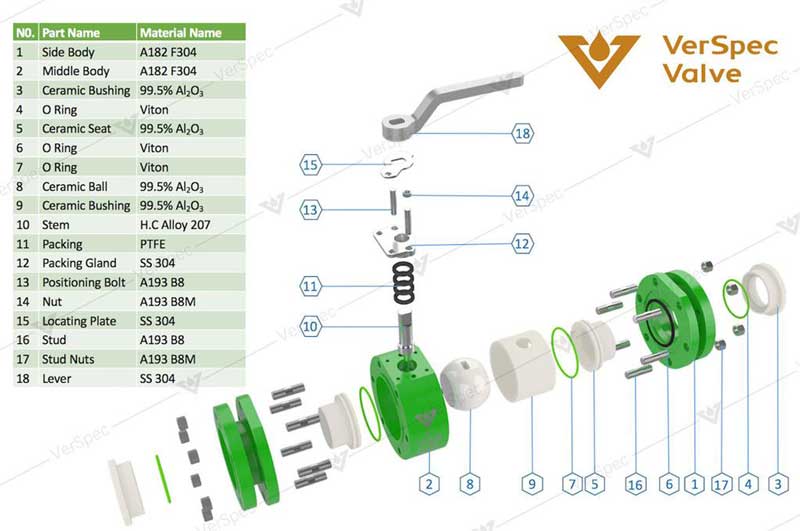

Why Choose a VerSpec Ceramic Ball Valve?

Due to the advanced properties of the technical ceramics used, VerSpec Ceramic Ball Valves offer significant advantages over standard material ball valves. VerSpec valves are manufactured using solid 99% above high-purity alumina ceramic, guaranteeing a valve that is superior in all respects, including resistance to abrasion, cavitation and corrosion.

• Corrosion.

99.5% alumina ceramic is virtually inert to almost all organic and inorganic chemicals. They do not interact with, nor contaminate the process media. They are physically and chemically stable against most acids and alkalis, and offer years of service with little or no corrosive degradation.

• Abrasion.

99.5% alumina ceramic is 43% harder than zirconia, 140% harder than porcelain, and 730% harder than stainless steel, an indication of the long- term wear-resistance properties of our valve materials.

• Cavitation.

Even severe, continuous cavitation will not degrade or damage our ceramic valve components. Therefore, the VerSpec Ceramic Ball Valve may be used in cavitating or high differential-pressure Applications with little or no harmful effects.

• Wide Selection of Trims.

Each valve size offers a variety of four to five different control and round-ported valve trims. This assures highly accurate, tailored flow control as well as minimizing seat and pipe abrasion due to oversized trims.

• 6 Months Warranty

By utilizing a ceramic material that is both corrosion and abrasion- resistant, we offer an extra level of security to our customers by offering up to 6 months warranty against corrosion, abrasion.

Model:CSCV-24R155

Standard:API 6D

Size:DN100-DN400

Pressure:PN10-PN16

Estimate Delivery:45 days

Model:CAFV-64F155

Standard:ASME B16.34

Size:DN80-DN350

Pressure:PN10

Estimate Delivery:35 days

Model:CKGV-17R151

Standard:MSS or Customized

Size:DN50-DN800

Pressure:PN10-PN25

Estimate Delivery:20 days upon receipt prepayment days

Model:CASS-64RW15

Standard:Factory Standard

Size:DN100-DN350

Pressure:150, PN16, PN10

Estimate Delivery:30 Days days