1. What is the function of the knife gate valve

The gate has two sealing surfaces. The gate of the wedge knife gate valve can be placed as a whole, called a rigid gate; to improve its manufacturability, instead of the deviation of the angle of the sealing surface during the processing, this gate is called Flexible gate. When the knife gate valve is closed, the sealing surface can only allow medium pressure to seal.

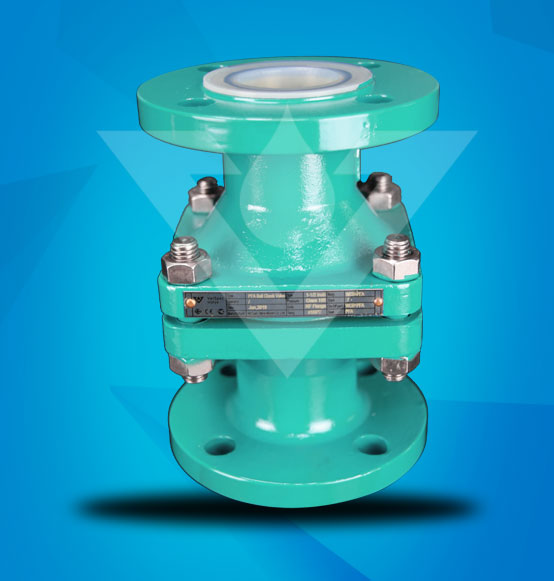

2. What is a knife gate valve

Knife gate valve, also known as knife gate valve, knife gate valve, slurry valve, mud valve, its opening and closing part is a gate, the direction of movement of the gate is perpendicular to the direction of the fluid, and it is cut off by a blade-shaped gate that can cut fiber materials. medium. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used model gate valve form a wedge. The wedge angle varies with valve parameters, usually 50. The gate of the wedge knife gate valve can be formed as a whole, called Rigid gate. It is also possible to manufacture a gate that can produce microscopic deformation to improve its manufacturability and the deviation produced during the processing. This kind of gate is called an elastic gate.

There is no cavity in the valve body. The gate is raised and lowered in the side guide groove and pressed against the valve seat by the lugs at the bottom. If a higher medium tightness is required, an O-shaped sealing valve seat can be used. Two-way sealing. The knife gate valve has a small installation space, low working pressure, is not easy to accumulate debris, and the price is reduced.

3. Knife gate valve installation and instructions

1. Before installing the knife gate valve, check the valve cavity and sealing surface for dirt or sand adhesion;

2. The bolts of each connection part must be fully tightened;

3. Check that the packing parts are required to be pressed tightly, not only to ensure the tightness of the packing, but also to ensure the flexible opening of the gate;

4. Before installing the valve, the user must check the valve model, connection size and pay attention to the flow direction of the medium to ensure consistency with the valve requirements;

5. When installing the valve, the user must supplement the necessary space for valve drive;

6. The wiring of the drive device must be carried out according to the wiring diagram;

7. The knife gate valve must be maintained regularly, and no collision or squeeze is allowed to avoid affecting the seal.

Company Profile

2005——Start to produce ceramic lined valve series.

2006——Start to produce rubber seat dome valve, knife gate valve and pinch valves.

2010——Joint venture start to produce Teflon plastic lined valve series.

2016——VerSpec US warehouse operated in Akensas.

2018——VerSpec Korea branch operated in Cheonnam.

2019——VerSpec India and VerSpec Mexico start operating.

Tel: +86-577-57666870

Fax:+86-577-56769885

E-mail: info@verspec.com

Español

Español